Measurement Consulting

Measurement Consulting

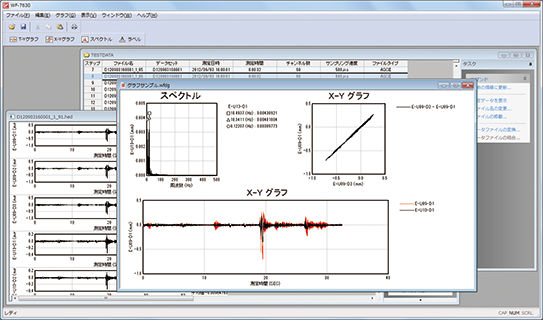

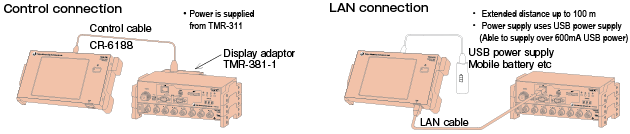

In the measurement business until now, there are many measuring methods which place importance on measurement done in the past, and inevitably, the latest technology is not in the process, such as cases where optimal pricing is not considered. While giving importance to conventional measurement methods, our measurement consulting goes on to take both site conditions and technology advancement into consideration in real time, allowing us to draw up a plan, project phases, and study that meet the needs of the client with the particular project, and to make a proposal that meets not only technological requirements, but budgetary ones as well. In addition to a measurement project and proposal, we also build a measurement system compatible with ubiquitous networking, and in some instances we may go beyond primary processing of measurement data (physical quantities conversion) onto secondary data processing (evaluation) so as to meet client needs.

We will propose a management and measurement system that utilizes information and communication devices in order to achieve more efficient measurement.

See [Home > Field sites] for case studies where measuring systems have been introduced in different kinds of construction projects.