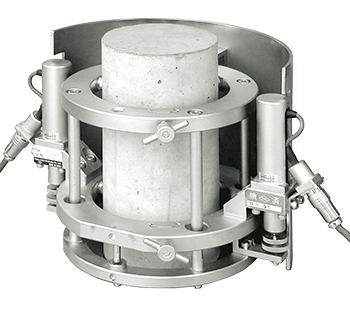

Concrete Compression Testing Sensor CLL-NA

CLL-NA Compression Load Cell

500kN to 1MN

This is a load cell with a flat loading surface. It is used to conduct strength tests on cylindrical concrete specimens. Guide marks on the loading surface allow cylindrical concrete specimens of different sizes to be easily aligned.

Protection ratings : IP 65 equivalent

- Features

- Convenient guide marks

- Easy handling

-

Specifications

Type Applied specimen Capacity Rated output Non-linearity Temperature range CLL-500KNA ø10 x 20 cm 500 kN 1.5 mV/V

(3000 x 10-6 strain) ±0.5 %0.2 %RO -20 to +70 ℃ CLL-1MNA ø15 x 30 cm 1 MN

More Information