Tie-rod Loadcell

Tie-rod Loadcell TCLT-NA

The TCLT-NA is a load cell designed to measure the tensile and compressive force applied to the tie-rod of a car.

- Features

- Easy installation using connection thread between tie-rod and tie-rod end

- 3 kinds of thread prepared for installation on various tie-rods

- 6 types are available depending on the combination of thread and capacity

-

Specifications

Type Capacity Mounting screw Rated output Nonlinearity Allowable temperature range TCLT-2KNA-10 2kN M10 × 1.25 Approx.1500 × 10-6

strain0.5%RO -10 to +60℃ TCLT-5KNA-10 5kN Approx.2000 × 10-6

strainTCLT-5KNA-12 M12 × 1.25 TCLT-10KNA-12 10kN TCLT-10KNA-14 M14 × 1.5 TCLT-20KNA-14 20kN Approx.3000 × 10-6 strain

Tie-rod Loadcell

Junction Box

Junction Box JB-2/JB-4

This junction box is used to connect two or four strain gauge type transducers and average the outputs of those transducers. The mean value is easily measured by a digital indicator or data logger.

It can also be used as a branching box to divide the connection of switching boxes into two or four series.

-

Specifications

Type JB-2/JB-4 Number of input points JB-2 : 2

JB-4 : 4Dimensions 80(W) x 50(H) x 120(D)mm Weight Approx. 220g

Examples of use

Example of use as an input averaging junction box

・Strain gauge type transducers to be connected must be of the same capacity, rated output and input/output resistance

・The input/output resistance viewed from the instrument is as follows.

(Input/output resistance of one transducer) divided by (Number of connected transducers).

The calculated value above must be within the range of the instrument specification.

Example of use as a branching box

As the inside of the junction box is wired with 7 wires (for terminals A to G), the junction box can also be used as a branching box as the above. Each connection between the data logger, junction box and switching boxes must be made using an exclusive 7-core cable specified by us.

Junction Box

Stress Gauge

SF series Stress gauge

These gauges are intended to measure the stress in an optional direction of the specimen in plane stress field. The gauges are sensitive not only in these axial direction but also in the transverse direction, and the sensitivity ratio of the transverse direction to the axial directions is equal to the Poisson’s ratio of the specimen material. In addition, the gauges are not sensitive to the shearing strain. Accordingly, the output of the gauges is proportional to the stress in the axial direction. The gauges are available in three types depending on the Poisson’s ratio of the specimen material.

| Applicable specimen | Metal |

|---|---|

| Operational temperature(℃) | -20 to +200℃ |

| Temperature compensation range(℃) | +10 to +100℃ |

| Applicable adhesive | NP-50B, CN, C-1 |

| Backing | Polyimide |

| Element | Cu-Ni |

| Strain limit | - |

| Fatigue life at room temperature | 1 x 106 (±1500 x 10-6 strain) |

-

AXIAL STRESS MEASUREMENT

Gauge pattern Type Gauge

length

(mm)Gauge

width

(mm)Backing

length

(mm)Backing

width

(mm)Resistance

(Ω)

Poisson's

ratio

of specimen

SFA-285-11 4 3 9 6 120 0.285 SFA-305-17 4 3 9 6 120 0.305 SFA-330-23 4 3 9 6 120 0.330 Each package contains 10 gauges.

Lead wire attachment service is available on request.

More Information

Stress Gauge

Crack Detection Gauge

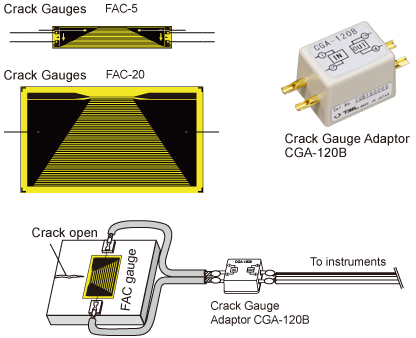

FAC series Crack detection gauge

FAC series crack detection gauges are designed to measure the length and propagation speed of cracks occurring as a result of metal fatigue in machinery, ships, aircraft, and automobiles. A gauge is adhered beforehand where cracks have occurred or are predicted to occur. As a crack progresses, the grid lines separate one after another, and output value changes. Use together with the special adaptor CGA-120B.

| Applicable specimen | Metal, Concrete |

|---|---|

| Operational temperature(℃) | -30 to +80℃ |

| Temperature compensation range(℃) | - |

| Applicable adhesive | CN, RP-2 |

| Backing | Special plastics |

| Element | Cu-Ni |

| Strain limit | - |

| Fatigue life at room temperature | - |

-

CRACK LENGTH AND PROPAGATION MEASUREMENT

Type Measuring

range

(mm)Backing

length

(mm)Backing

width

(mm)Gauge

resistance

(Ω)Grid

interval

(mm)Number

of gridFAC-5 4.5 28 5 1 0.1 46 FAC-20 20 43 25 1 0.5 41 Each package contains 10 gauges.

Type Number of channels Operational temperature Dimension Weight CGA-120B 1 -30 to +80℃

(except condensation)20(W) x 15(H) x 15(D)mm

(except projections)Approx.5g

More Information

Crack Detection Gauge

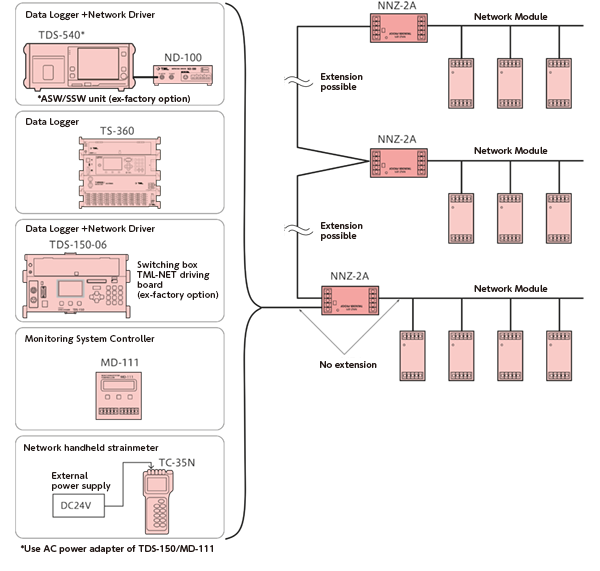

Thunder proof for TML-NET

Thunder proof for TML-NET NNZ-2A

The NNZ-2A is used for protecting TML-NET network measurement system from induced lightning. When the cable of instrument or network-module receives induced lightning, failure may be caused in the network driver and/or network module by the lightning surge. The NNZ-2A is connected to the connection cable of the network, and works to flow the surge current to the earth when induced lightning occurs. In addition, during standby of measurement, it automatically shuts off the network line to protect the network driver and network modules from the lightning surge.

- Features

- Shuts off network line automatically during measurement standby status to avoid induced current

- Power is supplied from network line

- Monitors voltage of network line and current of network modules, and shuts off immediately if abnormal condition occurs

-

Specifications

Type NNZ-2A Surge tolerance 100A (8/20µs impulse) Available number for one system NNZ-2A: up to 10

Low-comsumption network module: up to 100Rated power supply voltage DC18 to 24V Standard used cable Dedicated 2-conductor shielded cable

Total extended distance: up to 2 km (at DC24V power supply voltage)

up to 1 km (at DC18V power supply voltage)Display function Drop of voltage in the network line

Over current of network module (Shuts off the network modules at over current)Environment -20 to +60°C 85%RH or less (no condensation) Dimensions 50(W) x 28(H) x 100(D)mm (except projecting parts) Weight Approx. 120g

System Block Diagram

More Information