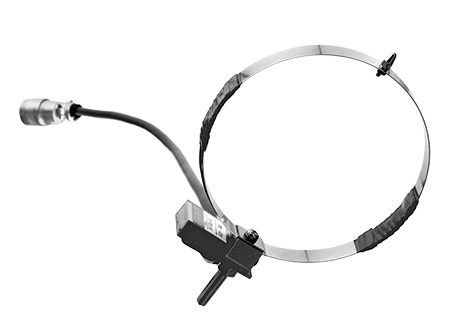

Ring type Displacement Transducer

OU Ring type Displacement Transducer

10mm to 30mm

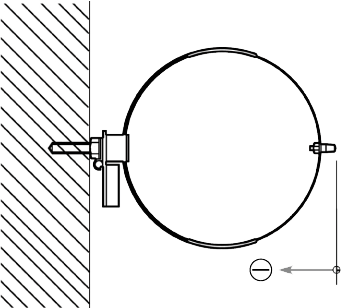

The OU displacement transducer is a combination of a round plate spring and strain gauges. It is mounted with its contact tip pressed against a structure. When displacement occurs in the structure, the plate spring is deformed and an output proportional to the displacement can be output.

- Features

- High Response

- Stable measurement with simple shape

- Easy handling

-

Specifications

Type Capacity Rated output Sensitivity

(x 10-6 strain/mm)Non-linearity Temperature range OU-10 10mm Approx. 5mV/V

(10000 x 10-6 strain)Approx. 1000 1%RO 0 to +40℃ OU-20 20mm Approx. 500 OU-30 30mm approx. 300 Output polarity

Measurement moves in the minus direction when the contact tip is pushed inward.

More Information

Strain gauge Users' Guide

Temperature Gauge

Strain gauge Users' Guide

Strain gauge Users' Guide

Strain Gauge Performance Characteristics

A wide range of TML strain gauges are available to match diverse measuring conditions. Since strain gauges provide their designed functions only when they are attached to specimens, it is important to select the most appropriate gauge type in consideration of the specimen material type, gauge type in consideration of the specimen material type, operating temperature, measurement environment and installation dimensions. The Strain Gauge Users' Guide provide inexperience users with comprehensive information on strain gauges, covering various subjects ranging from step-by-step strain gauge installation instructions to cautions in handling strain gauges. The Strain Gauge Performance Characteristics compile a guide to the technology of current strain gauge for use in consideration of a limit in detection with regard to the materials and size of a test specimen, humidity, the amount of strain, speed, fatigue, environments, etc..

Spot Welder

Flange Mounting-type Torque Transducer

LTB-NA Torque Transducer 10N・m to 1kN・m

The LTB-NA Torque Transducer is a flange-mounted transducer that is installed between non-rotating measuring items in order to detect torque in the items.

Protection ratings : IP 30 equivalent

- Features

- Measurable without the effect of bending

- Easy installation with flanges

-

Specifications

Type Capacity Rated output Non-linearity Temperature

rangeLTB-10NA 10N・m 1mV/V

(2000x10-6strain)±2%0.3%RO -10 to +60℃ LTB-20NA 20N・m LTB-30NA 30N・m LTB-50NA 50N・m LTB-100NA 100N・m LTB-200NA 200N・m LTB-300NA 300N・m LTB-500NA 500N・m LTB-1KNA 1kN・m

More Information

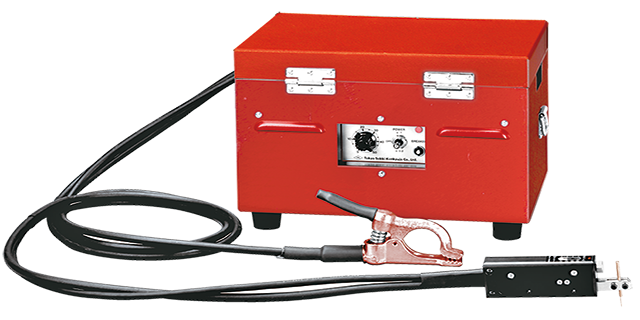

Spot Welder

SPOT WELDER W-50RC

This is a capacitive charge spot welder used for installing weldable strain gauges and fixing lead wires. The welding energy is controlled in 2 ranges of 1~10/5~50 watt second continuously, and a stabilizing circuit cancels the effect of changes in the power source voltage. Projecting parts such as electrical cables is packed inside, it is extremely convenient for field applications.

| Dimensions | 300(W)x195(H)x195(D)mm |

|---|---|

| Weight | 13kgs. |

| Power source | 90 to 110V ac |

| Welding energy | 1 to 10 watt sec./5 to 50 watt sec. continuous 60 watt sec. Max. (110V ac. 50Hz) |

| Output voltage | Approx. 32V Max. |

| Output pulse width | Approx. 5 msec. |

| Repetion use | 2 welds/sec. at 50 watt sec. |

More Information

Temperature Gauge

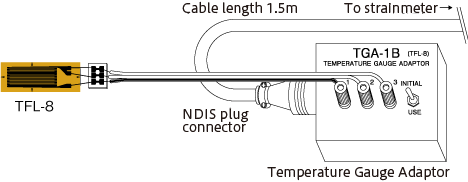

TF series Temperature gauge

These gauges are bonded on the specimen surface like ordinary strain gauges, and measures the surface temperature. By combining with the dedicated temperature gauge adaptor (TGA), actual temperature can be measured easily using a strainmeter.

| Applicable specimen | General |

|---|---|

| Operational temperature | -20 to +200°C |

| Temperature compensation range | - |

| Applicable adhesive | NP-50B, CN, C-1 |

| Backing | Polyimide |

| Element | Ni alloy |

| Strain limit | - |

| Fatigue life at room temperature | - |

-

TEMPERATURE GAUGE

Gauge pattern Type Gauge length

(mm)Gauge width

(mm)Backing length

(mm)Backing

width (mm)Resistance (Ω) Sensitivity (Ω/℃)

TFL-2-60 2 1.9 6.1 3.5 60 0.34 approx. TFL-3-60 3 3.2 8.5 5 60 0.34 approx. TFL-6-60 6 2.6 12.4 4.5 60 0.34 approx. TFL-8 8 3.5 14 5.5 120 0.68 approx. Leadwire-integral service is available on request.

-

TGA-1A/TGA-1B Temperature Gauge Adaptor Optional

This adaptor is provided with temperature gauge TF series for direct reading of temperature with optional strainmeter, and converts output to 100×10-6 strain/℃.

Type of Adaptor Type Temperature (℃) Sensitivity (x10-6 strain/℃) Accuracy (℃) Bridge mode Dimensions (W)

x (H)

x (D)Weight (g) TGA-1A TFL-2-60 -20 to +200 100 ±1,or less Full bridge 100 x 40 x 70 370 TFL-3-60 TFL-6-60 TGA-1B TFL-8

More Information

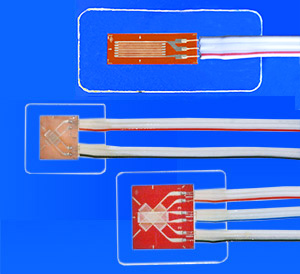

Waterproof strain gauge

WF series Waterproof strain gauge

This is WF-series water proof type strain gauge having a pre-attached vinyl lead wire and an entire coating with epoxy resin. The coating is transparent and flexible, which ensures easy installation of the gauge.

| Applicable specimen | Metal, Glass, Ceramics |

|---|---|

| Operational temperature(℃) | 0 to +80℃ |

| Temperature compensation range(℃) | +10 to +80℃ |

| Applicable adhesive | CN, P-2 |

| Backing | Epoxy |

| Element | Cu-Ni |

| Strain limit | 3% (30000 x 10-6 strain) |

| Fatigue life at room temperature | 3 x 104 (±1500 x 10-6 strain) |

-

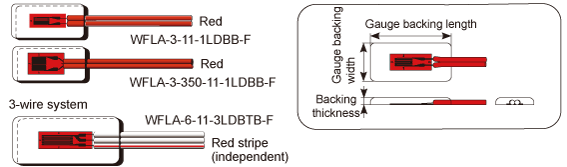

Single-element (G.F. 2.1 approx.)

0.08mm2 integral vinyl leadwire Total leadwire resistance per meter : 0.44Ω

Type Gauge Backing Resist-ance

(Ω)Lead wire pre-attached Type name of lead wire preattached length

(mm)width

(mm)length

(mm)width

(mm)thickness

(mm)WFLA-3-11

WFLA-3-17

WFLA-3-233 1.7 17 8 1.5 120 Paralleled 1m

Paralleled 3m

Paralleled 5m

3-wire 3m

3-wire 5m-1LDBB

-3LDBB

-5LDBB

-3LDBTB

-5LDBTBWFLA-3-350-11

WFLA-3-350-17

WFLA-3-350-233 3.2 17 8 1.5 350 Paralleled 1m

Paralleled 3m

Paralleled 5m-1LDBB

-3LDBB

-5LDBBWFLA-6-11

WFLA-6-17

WFLA-6-236 2.2 25 11 1.5 120 Paralleled 1m

Paralleled 3m

Paralleled 5m

3-wire 3m

3-wire 5m-1LDBB

-3LDBB

-5LDBB

-3LDBTB

-5LDBTBEach package contains 10 gauges.

-

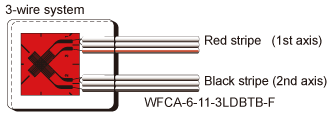

90° 2-element Rosette Stacked type(G.F. 2.1 approx.)

0.08mm2 integral vinyl leadwire Total leadwire resistance per meter : 0.44Ω

Type Gauge Backing Resist-ance

(Ω)Lead wire pre-attached Type name of lead wire preattached length

(mm)width

(mm)length

(mm)width

(mm)thickness

(mm)WFCA-3-11

WFCA-3-17

WFCA-3-233 1.7 19 16 1.5 120 Paralleled 1m

Paralleled 3m

Paralleled 5m

3-wire 3m

-wire 5m-1LDBB

-3LDBB

-5LDBB

-3LDBTB

-5LDBTBWFCA-6-11

WFCA-6-17

WFCA-6-236 2.3 25 21 1.5 120 Paralleled 1m

Paralleled 3m

Paralleled 5m

3-wire 3m

3-wire 5m-1LDBB

-3LDBB

-5LDBB

-3LDBTB

-5LDBTBEach package contains 10 gauges.

-

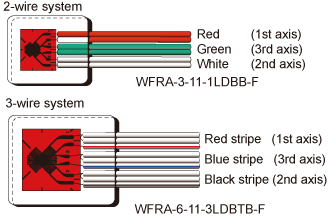

45°/90°3-element Rosette Stacked type (G.F. 2.1 approx.)

0.08mm2 integral vinyl leadwire Total leadwire resistance per meter : 0.44Ω

Type Gauge Backing Resist-ance

(Ω)Lead wire pre-attached Type name of lead wire preattached length

(mm)width

(mm)length

(mm)width

(mm)thickness

(mm)WFRA-3-11

WFRA-3-17

WFRA-3-233 1.7 19 16 1.5 120 Paralleled 1m

Paralleled 3m

Paralleled 5m

3-wire 3m

3-wire 5m-1LDBB

-3LDBB

-5LDBB

-3LDBTB

-5LDBTBWFRA-6-11

WFRA-6-17

WFRA-6-236 2.3 25 21 1.5 120 Paralleled 1m

Paralleled 3m

Paralleled 5m

3-wire 3m

3-wire 5m-1LDBB

-3LDBB

-5LDBB

-3LDBTB

-5LDBTBEach package contains 10 gauges.

More Information